System that transfers heat from one space to another

This article is about devices used to heat and potentially also cool a building (or water) using the refrigeration cycle. For more about the theory, see Heat pump and refrigeration cycle. For details of the most common type, see air source heat pump. For a similar device for cooling only, see air conditioner. For heat pumps used to keep food cool, see refrigerator. For other uses, see Heat pump (disambiguation).

External heat exchanger of an air-source heat pump for both heating and cooling

External heat exchanger of an air-source heat pump for both heating and cooling

Mitsubishi heat pump interior air handler wall unit

Mitsubishi heat pump interior air handler wall unit

A heat pump is a device that consumes energy (usually electricity) to transfer heat from a cold heat sink to a hot heat sink. Specifically, the heat pump transfers thermal energy using a refrigeration cycle, cooling the cool space and warming the warm space.[1] In cold weather, a heat pump can move heat from the cool outdoors to warm a house (e.g. winter); the pump may also be designed to move heat from the house to the warmer outdoors in warm weather (e.g. summer). As they transfer heat rather than generating heat, they are more energy-efficient than other ways of heating or cooling a home.[2]

A gaseous refrigerant is compressed so its pressure and temperature rise. When operating as a heater in cold weather, the warmed gas flows to a heat exchanger in the indoor space where some of its thermal energy is transferred to that indoor space, causing the gas to condense to its liquid state. The liquified refrigerant flows to a heat exchanger in the outdoor space where the pressure falls, the liquid evaporates and the temperature of the gas falls. It is now colder than the temperature of the outdoor space being used as a heat source. It can again take up energy from the heat source, be compressed and repeat the cycle.

Air source heat pumps are the most common models, while other types include ground source heat pumps, water source heat pumps and exhaust air heat pumps.[3] Large-scale heat pumps are also used in district heating systems.[4]

The efficiency of a heat pump is expressed as a coefficient of performance (COP), or seasonal coefficient of performance (SCOP). The higher the number, the more efficient a heat pump is. For example, an air-to-water heat pump that produces 6kW at a SCOP of 4.62 will give over 4kW of energy into a heating system for every kilowatt of energy that the heat pump uses itself to operate. When used for space heating, heat pumps are typically more energy-efficient than electric resistance and other heaters.

Because of their high efficiency and the increasing share of fossil-free sources in electrical grids, heat pumps are playing a role in climate change mitigation.[5][6] Consuming 1 kWh of electricity, they can transfer 1[7] to 4.5 kWh of thermal energy into a building. The carbon footprint of heat pumps depends on how electricity is generated, but they usually reduce emissions.[8] Heat pumps could satisfy over 80% of global space and water heating needs with a lower carbon footprint than gas-fired condensing boilers: however, in 2021 they only met 10%.[4]

Principle of operation

[edit]

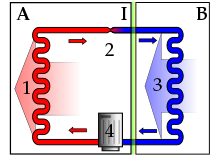

A: indoor compartment, B: outdoor compartment, I: insulation, 1: condenser, 2: expansion valve, 3: evaporator, 4: compressor

A: indoor compartment, B: outdoor compartment, I: insulation, 1: condenser, 2: expansion valve, 3: evaporator, 4: compressor

Main articles: Heat pump and refrigeration cycle and Vapor-compression refrigeration

Heat flows spontaneously from a region of higher temperature to a region of lower temperature. Heat does not flow spontaneously from lower temperature to higher, but it can be made to flow in this direction if work is performed. The work required to transfer a given amount of heat is usually much less than the amount of heat; this is the motivation for using heat pumps in applications such as the heating of water and the interior of buildings.[9]

The amount of work required to drive an amount of heat Q from a lower-temperature reservoir such as ambient air to a higher-temperature reservoir such as the interior of a building is:  where

where

is the work performed on the working fluid by the heat pump's compressor.

is the work performed on the working fluid by the heat pump's compressor. is the heat transferred from the lower-temperature reservoir to the higher-temperature reservoir.

is the heat transferred from the lower-temperature reservoir to the higher-temperature reservoir. is the instantaneous coefficient of performance for the heat pump at the temperatures prevailing in the reservoirs at one instant.

is the instantaneous coefficient of performance for the heat pump at the temperatures prevailing in the reservoirs at one instant.

The coefficient of performance of a heat pump is greater than one so the work required is less than the heat transferred, making a heat pump a more efficient form of heating than electrical resistance heating. As the temperature of the higher-temperature reservoir increases in response to the heat flowing into it, the coefficient of performance decreases, causing an increasing amount of work to be required for each unit of heat being transferred.[9]

The coefficient of performance, and the work required by a heat pump can be calculated easily by considering an ideal heat pump operating on the reversed Carnot cycle:

- If the low-temperature reservoir is at a temperature of 270 K (−3 °C) and the interior of the building is at 280 K (7 °C) the relevant coefficient of performance is 27. This means only 1 joule of work is required to transfer 27 joules of heat from a reservoir at 270 K to another at 280 K. The one joule of work ultimately ends up as thermal energy in the interior of the building so for each 27 joules of heat that are removed from the low-temperature reservoir, 28 joules of heat are added to the building interior, making the heat pump even more attractive from an efficiency perspective.[note 1]

- As the temperature of the interior of the building rises progressively to 300 K (27 °C) the coefficient of performance falls progressively to 9. This means each joule of work is responsible for transferring 9 joules of heat out of the low-temperature reservoir and into the building. Again, the 1 joule of work ultimately ends up as thermal energy in the interior of the building so 10 joules of heat are added to the building interior.[note 2]

This is the theoretical amount of heat pumped but in practice it will be less for various reasons, for example if the outside unit has been installed where there is not enough airflow. More data sharing with owners and academics—perhaps from heat meters—could improve efficiency in the long run.[11]

History

[edit]

Milestones:

- 1748

- William Cullen demonstrates artificial refrigeration.[12]

- 1834

- Jacob Perkins patents a design for a practical refrigerator using dimethyl ether.[13]

- 1852

- Lord Kelvin describes the theory underlying heat pumps.[14]

- 1855–1857

- Peter von Rittinger develops and builds the first heat pump.[15]

- 1877

- In the period before 1875, heat pumps were for the time being pursued for vapour compression evaporation (open heat pump process) in salt works with their obvious advantages for saving wood and coal. In 1857, Peter von Rittinger was the first to try to implement the idea of vapor compression in a small pilot plant. Presumably inspired by Rittinger's experiments in Ebensee, Antoine-Paul Piccard from the University of Lausanne and the engineer J. H. Weibel from the Weibel–Briquet company in Geneva built the world's first really functioning vapor compression system with a two-stage piston compressor. In 1877 this first heat pump in Switzerland was installed in the Bex salt works.[14][16]

- 1928

- Aurel Stodola constructs a closed-loop heat pump (water source from Lake Geneva) which provides heating for the Geneva city hall to this day.[17]

- 1937–1945

- During the First World War, fuel prices were very high in Switzerland but it had plenty of hydropower.[14]: 18 In the period before and especially during the Second World War, when neutral Switzerland was completely surrounded by fascist-ruled countries, the coal shortage became alarming again. Thanks to their leading position in energy technology, the Swiss companies Sulzer, Escher Wyss and Brown Boveri built and put in operation around 35 heat pumps between 1937 and 1945. The main heat sources were lake water, river water, groundwater, and waste heat. Particularly noteworthy are the six historic heat pumps from the city of Zurich with heat outputs from 100 kW to 6 MW. An international milestone is the heat pump built by Escher Wyss in 1937/38 to replace the wood stoves in the City Hall of Zurich. To avoid noise and vibrations, a recently developed rotary piston compressor was used. This historic heat pump heated the town hall for 63 years until 2001. Only then was it replaced by a new, more efficient heat pump.[14]

- 1945

- John Sumner, City Electrical Engineer for Norwich, installs an experimental water-source heat pump fed central heating system, using a nearby river to heat new Council administrative buildings. It had a seasonal efficiency ratio of 3.42, average thermal delivery of 147 kW, and peak output of 234 kW.[18]

- 1948

- Robert C. Webber is credited as developing and building the first ground-source heat pump.[19]

- 1951

- First large scale installation—the Royal Festival Hall in London is opened with a town gas-powered reversible water-source heat pump, fed by the Thames, for both winter heating and summer cooling needs.[18]

- 2019

- The Kigali Amendment to phase out harmful refrigerants takes effect.

Types

[edit]

Air-source

[edit]

This section is an excerpt from Air source heat pump.[edit]

Heat pump on balcony of apartment

Heat pump on balcony of apartment

An air source heat pump (ASHP) is a heat pump that can absorb heat from air outside a building and release it inside; it uses the same vapor-compression refrigeration process and much the same equipment as an air conditioner, but in the opposite direction. ASHPs are the most common type of heat pump and, usually being smaller, tend to be used to heat individual houses or flats rather than blocks, districts or industrial processes.[20][21]

Air-to-air heat pumps provide hot or cold air directly to rooms, but do not usually provide hot water. Air-to-water heat pumps use radiators or underfloor heating to heat a whole house and are often also used to provide domestic hot water.

An ASHP can typically gain 4 kWh thermal energy from 1 kWh electric energy. They are optimized for flow temperatures between 30 and 40 °C (86 and 104 °F), suitable for buildings with heat emitters sized for low flow temperatures. With losses in efficiency, an ASHP can even provide full central heating with a flow temperature up to 80 °C (176 °F).[22]

As of 2023[update] about 10% of building heating worldwide is from ASHPs. They are the main way to phase out gas boilers (also known as "furnaces") from houses, to avoid their greenhouse gas emissions.[23]

Air-source heat pumps are used to move heat between two heat exchangers, one outside the building which is fitted with fins through which air is forced using a fan and the other which either directly heats the air inside the building or heats water which is then circulated around the building through radiators or underfloor heating which releases the heat to the building. These devices can also operate in a cooling mode where they extract heat via the internal heat exchanger and eject it into the ambient air using the external heat exchanger. Some can be used to heat water for washing which is stored in a domestic hot water tank.[24]

Air-source heat pumps are relatively easy and inexpensive to install, so are the most widely used type. In mild weather, coefficient of performance (COP) may be between 2 and 5, while at temperatures below around −8 °C (18 °F) an air-source heat pump may still achieve a COP of 1 to 4.[25]

While older air-source heat pumps performed relatively poorly at low temperatures and were better suited for warm climates, newer models with variable-speed compressors remain highly efficient in freezing conditions allowing for wide adoption and cost savings in places like Minnesota and Maine in the United States.

[26]

Ground source

[edit]

This section is an excerpt from Ground source heat pump.[edit]

A heat pump in combination with heat and cold storage

A heat pump in combination with heat and cold storage

A ground source heat pump (also geothermal heat pump) is a heating/cooling system for buildings that use a type of heat pump to transfer heat to or from the ground, taking advantage of the relative constancy of temperatures of the earth through the seasons. Ground-source heat pumps (GSHPs) – or geothermal heat pumps (GHP), as they are commonly termed in North America – are among the most energy-efficient technologies for providing HVAC and water heating, using far less energy than can be achieved by burning a fuel in a boiler/furnace or by use of resistive electric heaters.

Efficiency is given as a coefficient of performance (CoP) which is typically in the range 3 – 6, meaning that the devices provide 3 – 6 units of heat for each unit of electricity used. Setup costs are higher than for other heating systems, due to the requirement to install ground loops over large areas or to drill bore holes, and for this reason, ground source is often suitable when new blocks of flats are built.

[27] Otherwise air-source heat pumps are often used instead.

Heat recovery ventilation

[edit]

Main article: Heat recovery ventilation

Exhaust air heat pumps extract heat from the exhaust air of a building and require mechanical ventilation. Two classes exist:

- Exhaust air-air heat pumps transfer heat to intake air.

- Exhaust air-water heat pumps transfer heat to a heating circuit that includes a tank of domestic hot water.

Solar-assisted

[edit]

This section is an excerpt from Solar-assisted heat pump.[edit]

Hybrid photovoltaic-thermal solar panels of a SAHP in an experimental installation at Department of Energy at Polytechnic of Milan

Hybrid photovoltaic-thermal solar panels of a SAHP in an experimental installation at Department of Energy at Polytechnic of Milan

A solar-assisted heat pump (SAHP) is a machine that combines a heat pump and thermal solar panels and/or PV solar panels in a single integrated system.[28] Typically these two technologies are used separately (or only placing them in parallel) to produce hot water.[29] In this system the solar thermal panel performs the function of the low temperature heat source and the heat produced is used to feed the heat pump's evaporator.[30] The goal of this system is to get high coefficient of performance (COP) and then produce energy in a more efficient and less expensive way.

It is possible to use any type of solar thermal panel (sheet and tubes, roll-bond, heat pipe, thermal plates) or hybrid (mono/polycrystalline, thin film) in combination with the heat pump. The use of a hybrid panel is preferable because it allows covering a part of the electricity demand of the heat pump and reduce the power consumption and consequently the variable costs of the system.

Water-source

[edit]

Water-source heat exchanger being installed

Water-source heat exchanger being installed

A water-source heat pump works in a similar manner to a ground-source heat pump, except that it takes heat from a body of water rather than the ground. The body of water does, however, need to be large enough to be able to withstand the cooling effect of the unit without freezing or creating an adverse effect for wildlife.[31] The largest water-source heat pump was installed in the Danish town of Esbjerg in 2023.[32][33]

Others

[edit]

A thermoacoustic heat pump operates as a thermoacoustic heat engine without refrigerant but instead uses a standing wave in a sealed chamber driven by a loudspeaker to achieve a temperature difference across the chamber.[34]

Electrocaloric heat pumps are solid state.[35]

Applications

[edit]

The International Energy Agency estimated that, as of 2021, heat pumps installed in buildings have a combined capacity of more than 1000 GW.[4] They are used for heating, ventilation, and air conditioning (HVAC) and may also provide domestic hot water and tumble clothes drying.[36] The purchase costs are supported in various countries by consumer rebates.[37]

Space heating and sometimes also cooling

[edit]

In HVAC applications, a heat pump is typically a vapor-compression refrigeration device that includes a reversing valve and optimized heat exchangers so that the direction of heat flow (thermal energy movement) may be reversed. The reversing valve switches the direction of refrigerant through the cycle and therefore the heat pump may deliver either heating or cooling to a building.

Because the two heat exchangers, the condenser and evaporator, must swap functions, they are optimized to perform adequately in both modes. Therefore, the Seasonal Energy Efficiency Rating (SEER in the US) or European seasonal energy efficiency ratio of a reversible heat pump is typically slightly less than those of two separately optimized machines. For equipment to receive the US Energy Star rating, it must have a rating of at least 14 SEER. Pumps with ratings of 18 SEER or above are considered highly efficient. The highest efficiency heat pumps manufactured are up to 24 SEER.[38]

Heating seasonal performance factor (in the US) or Seasonal Performance Factor (in Europe) are ratings of heating performance. The SPF is Total heat output per annum / Total electricity consumed per annum in other words the average heating COP over the year.[39]

Window mounted heat pump

[edit]

Saddle-style window mounted heat pump 3D sketch

Saddle-style window mounted heat pump 3D sketch

Window mounted heat pumps run on standard 120v AC outlets and provide heating, cooling, and humidity control. They are more efficient with lower noise levels, condensation management, and a smaller footprint than window mounted air conditioners that just do cooling.[40]

Water heating

[edit]

In water heating applications, heat pumps may be used to heat or preheat water for swimming pools, homes or industry. Usually heat is extracted from outdoor air and transferred to an indoor water tank.[41][42]

District heating

[edit]

Large (megawatt-scale) heat pumps are used for district heating.[43] However as of 2022[update] about 90% of district heat is from fossil fuels.[44] In Europe, heat pumps account for a mere 1% of heat supply in district heating networks but several countries have targets to decarbonise their networks between 2030 and 2040.[4] Possible sources of heat for such applications are sewage water, ambient water (e.g. sea, lake and river water), industrial waste heat, geothermal energy, flue gas, waste heat from district cooling and heat from solar seasonal thermal energy storage.[45] Large-scale heat pumps for district heating combined with thermal energy storage offer high flexibility for the integration of variable renewable energy. Therefore, they are regarded as a key technology for limiting climate change by phasing out fossil fuels.[45][46] They are also a crucial element of systems which can both heat and cool districts.[47]

Industrial heating

[edit]

There is great potential to reduce the energy consumption and related greenhouse gas emissions in industry by application of industrial heat pumps, for example for process heat.[48][49] Short payback periods of less than 2 years are possible, while achieving a high reduction of CO2 emissions (in some cases more than 50%).[50][51] Industrial heat pumps can heat up to 200 °C, and can meet the heating demands of many light industries.[52][53] In Europe alone, 15 GW of heat pumps could be installed in 3,000 facilities in the paper, food and chemicals industries.[4]

[edit]

Main article: Coefficient of performance

The performance of a heat pump is determined by the ability of the pump to extract heat from a low temperature environment (the source) and deliver it to a higher temperature environment (the sink).[54] Performance varies, depending on installation details, temperature differences, site elevation, location on site, pipe runs, flow rates, and maintenance.

In general, heat pumps work most efficiently (that is, the heat output produced for a given energy input) when the difference between the heat source and the heat sink is small. When using a heat pump for space or water heating, therefore, the heat pump will be most efficient in mild conditions, and decline in efficiency on very cold days. Performance metrics supplied to consumers attempt to take this variation into account.

Common performance metrics are the SEER (in cooling mode) and seasonal coefficient of performance (SCOP) (commonly used just for heating), although SCOP can be used for both modes of operation.[54] Larger values of either metric indicate better performance.[54] When comparing the performance of heat pumps, the term performance is preferred to efficiency, with coefficient of performance (COP) being used to describe the ratio of useful heat movement per work input.[54] An electrical resistance heater has a COP of 1.0, which is considerably lower than a well-designed heat pump which will typically have a COP of 3 to 5 with an external temperature of 10 °C and an internal temperature of 20 °C. Because the ground is a constant temperature source, a ground-source heat pump is not subjected to large temperature fluctuations, and therefore is the most energy-efficient type of heat pump.[54]

The "seasonal coefficient of performance" (SCOP) is a measure of the aggregate energy efficiency measure over a period of one year which is dependent on regional climate.[54] One framework for this calculation is given by the Commission Regulation (EU) No. 813/2013.[55]

A heat pump's operating performance in cooling mode is characterized in the US by either its energy efficiency ratio (EER) or seasonal energy efficiency ratio (SEER), both of which have units of BTU/(h·W) (note that 1 BTU/(h·W) = 0.293 W/W) and larger values indicate better performance.

COP variation with output temperature

| Pump type and source |

Typical use |

35 °C

(e.g. heated screed floor) |

45 °C

(e.g. heated screed floor) |

55 °C

(e.g. heated timber floor) |

65 °C

(e.g. radiator or DHW) |

75 °C

(e.g. radiator and DHW) |

85 °C

(e.g. radiator and DHW) |

| High-efficiency air-source heat pump (ASHP), air at −20 °C[56] |

|

2.2 |

2.0 |

†|

†|

†|

†|

| Two-stage ASHP, air at −20 °C[57] |

Low source temperature |

2.4 |

2.2 |

1.9 |

†|

†|

†|

| High-efficiency ASHP, air at 0 °C[56] |

Low output temperature |

3.8 |

2.8 |

2.2 |

2.0 |

†|

†|

Prototype transcritical CO

2 (R744) heat pump with tripartite gas cooler, source at 0 °C[58] |

High output temperature |

3.3 |

†|

†|

4.2 |

†|

3.0 |

| Ground-source heat pump (GSHP), water at 0 °C[56] |

|

5.0 |

3.7 |

2.9 |

2.4 |

†|

†|

| GSHP, ground at 10 °C[56] |

Low output temperature |

7.2 |

5.0 |

3.7 |

2.9 |

2.4 |

†|

| Theoretical Carnot cycle limit, source −20 °C |

|

5.6 |

4.9 |

4.4 |

4.0 |

3.7 |

3.4 |

| Theoretical Carnot cycle limit, source 0 °C |

|

8.8 |

7.1 |

6.0 |

5.2 |

4.6 |

4.2 |

Theoretical Lorentzen cycle limit (CO

2 pump), return fluid 25 °C, source 0 °C[58] |

|

10.1 |

8.8 |

7.9 |

7.1 |

6.5 |

6.1 |

| Theoretical Carnot cycle limit, source 10 °C |

|

12.3 |

9.1 |

7.3 |

6.1 |

5.4 |

4.8 |

[edit]

The carbon footprint of heat pumps depends on their individual efficiency and how electricity is produced. An increasing share of low-carbon energy sources such as wind and solar will lower the impact on the climate.

| heating system |

emissions of energy source |

efficiency |

resulting emissions for thermal energy |

| heat pump with onshore wind power |

11 gCO2/kWh[59] |

400% (COP=4) |

3 gCO2/kWh |

| heat pump with global electricity mix |

436 gCO2/kWh[60] (2022) |

400% (COP=4) |

109 gCO2/kWh |

| natural-gas thermal (high efficiency) |

201 gCO2/kWh[61] |

90%[citation needed] |

223 gCO2/kWh |

heat pump

electricity by lignite (old power plant)

and low performance |

1221 gCO2/kWh[61] |

300% (COP=3) |

407 gCO2/kWh |

In most settings, heat pumps will reduce CO2 emissions compared to heating systems powered by fossil fuels.[62] In regions accounting for 70% of world energy consumption, the emissions savings of heat pumps compared with a high-efficiency gas boiler are on average above 45% and reach 80% in countries with cleaner electricity mixes.[4] These values can be improved by 10 percentage points, respectively, with alternative refrigerants. In the United States, 70% of houses could reduce emissions by installing a heat pump.[63][4] The rising share of renewable electricity generation in many countries is set to increase the emissions savings from heat pumps over time.[4]

Heating systems powered by green hydrogen are also low-carbon and may become competitors, but are much less efficient due to the energy loss associated with hydrogen conversion, transport and use. In addition, not enough green hydrogen is expected to be available before the 2030s or 2040s.[64][65]

Operation

[edit]

See also: Vapor-compression refrigeration

|

|

This section needs additional citations for verification. Please help improve this article by adding citations to reliable sources in this section. Unsourced material may be challenged and removed. (May 2021) (Learn how and when to remove this message)

|

Figure 2: Temperature–entropy diagram of the vapor-compression cycle

Figure 2: Temperature–entropy diagram of the vapor-compression cycle

An internal view of the outdoor unit of an Ecodan air source heat pump

An internal view of the outdoor unit of an Ecodan air source heat pump

Large heat pump setup for a commercial building

Wiring and connections to a central air unit inside

Vapor-compression uses a circulating refrigerant as the medium which absorbs heat from one space, compresses it thereby increasing its temperature before releasing it in another space. The system normally has eight main components: a compressor, a reservoir, a reversing valve which selects between heating and cooling mode, two thermal expansion valves (one used when in heating mode and the other when used in cooling mode) and two heat exchangers, one associated with the external heat source/sink and the other with the interior. In heating mode the external heat exchanger is the evaporator and the internal one being the condenser; in cooling mode the roles are reversed.

Circulating refrigerant enters the compressor in the thermodynamic state known as a saturated vapor[66] and is compressed to a higher pressure, resulting in a higher temperature as well. The hot, compressed vapor is then in the thermodynamic state known as a superheated vapor and it is at a temperature and pressure at which it can be condensed with either cooling water or cooling air flowing across the coil or tubes. In heating mode this heat is used to heat the building using the internal heat exchanger, and in cooling mode this heat is rejected via the external heat exchanger.

The condensed, liquid refrigerant, in the thermodynamic state known as a saturated liquid, is next routed through an expansion valve where it undergoes an abrupt reduction in pressure. That pressure reduction results in the adiabatic flash evaporation of a part of the liquid refrigerant. The auto-refrigeration effect of the adiabatic flash evaporation lowers the temperature of the liquid and-vapor refrigerant mixture to where it is colder than the temperature of the enclosed space to be refrigerated.

The cold mixture is then routed through the coil or tubes in the evaporator. A fan circulates the warm air in the enclosed space across the coil or tubes carrying the cold refrigerant liquid and vapor mixture. That warm air evaporates the liquid part of the cold refrigerant mixture. At the same time, the circulating air is cooled and thus lowers the temperature of the enclosed space to the desired temperature. The evaporator is where the circulating refrigerant absorbs and removes heat which is subsequently rejected in the condenser and transferred elsewhere by the water or air used in the condenser.

To complete the refrigeration cycle, the refrigerant vapor from the evaporator is again a saturated vapor and is routed back into the compressor.

Over time, the evaporator may collect ice or water from ambient humidity. The ice is melted through defrosting cycle. An internal heat exchanger is either used to heat/cool the interior air directly or to heat water that is then circulated through radiators or underfloor heating circuit to either heat or cool the buildings.

[edit]

Main article: Subcooling

Heat input can be improved if the refrigerant enters the evaporator with a lower vapor content. This can be achieved by cooling the liquid refrigerant after condensation. The gaseous refrigerant condenses on the heat exchange surface of the condenser. To achieve a heat flow from the gaseous flow center to the wall of the condenser, the temperature of the liquid refrigerant must be lower than the condensation temperature.

Additional subcooling can be achieved by heat exchange between relatively warm liquid refrigerant leaving the condenser and the cooler refrigerant vapor emerging from the evaporator. The enthalpy difference required for the subcooling leads to the superheating of the vapor drawn into the compressor. When the increase in cooling achieved by subcooling is greater that the compressor drive input required to overcome the additional pressure losses, such a heat exchange improves the coefficient of performance.[67]

One disadvantage of the subcooling of liquids is that the difference between the condensing temperature and the heat-sink temperature must be larger. This leads to a moderately high pressure difference between condensing and evaporating pressure, whereby the compressor energy increases.

Refrigerant choice

[edit]

Main article: Refrigerant

Pure refrigerants can be divided into organic substances (hydrocarbons (HCs), chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), hydrofluoroolefins (HFOs), and HCFOs), and inorganic substances (ammonia (NH

3), carbon dioxide (CO

2), and water (H

2O)[68]).[69] Their boiling points are usually below −25 °C.[70]

In the past 200 years, the standards and requirements for new refrigerants have changed. Nowadays low global warming potential (GWP) is required, in addition to all the previous requirements for safety, practicality, material compatibility, appropriate atmospheric life,[clarification needed] and compatibility with high-efficiency products. By 2022, devices using refrigerants with a very low GWP still have a small market share but are expected to play an increasing role due to enforced regulations,[71] as most countries have now ratified the Kigali Amendment to ban HFCs.[72] Isobutane (R600A) and propane (R290) are far less harmful to the environment than conventional hydrofluorocarbons (HFC) and are already being used in air-source heat pumps.[73] Propane may be the most suitable for high temperature heat pumps.[74] Ammonia (R717) and carbon dioxide (R-744) also have a low GWP. As of 2023[update] smaller CO

2 heat pumps are not widely available and research and development of them continues.[75] A 2024 report said that refrigerants with GWP are vulnerable to further international restrictions.[76]

Until the 1990s, heat pumps, along with fridges and other related products used chlorofluorocarbons (CFCs) as refrigerants, which caused major damage to the ozone layer when released into the atmosphere. Use of these chemicals was banned or severely restricted by the Montreal Protocol of August 1987.[77]

Replacements, including R-134a and R-410A, are hydrofluorocarbons (HFC) with similar thermodynamic properties with insignificant ozone depletion potential (ODP) but had problematic GWP.[78] HFCs are powerful greenhouse gases which contribute to climate change.[79][80] Dimethyl ether (DME) also gained in popularity as a refrigerant in combination with R404a.[81] More recent refrigerants include difluoromethane (R32) with a lower GWP, but still over 600.

| refrigerant |

20-year GWP |

100-year GWP |

| R-290 propane[82] |

0.072 |

0.02 |

| R-600a isobutane |

|

3[83] |

| R-32[82] |

491 |

136 |

| R-410a[84] |

4705 |

2285 |

| R-134a[84] |

4060 |

1470 |

| R-404a[84] |

7258 |

4808 |

Devices with R-290 refrigerant (propane) are expected to play a key role in the future.[74][85] The 100-year GWP of propane, at 0.02, is extremely low and is approximately 7000 times less than R-32. However, the flammability of propane requires additional safety measures: the maximum safe charges have been set significantly lower than for lower flammability refrigerants (only allowing approximately 13.5 times less refrigerant in the system than R-32).[86][87][88] This means that R-290 is not suitable for all situations or locations. Nonetheless, by 2022, an increasing number of devices with R-290 were offered for domestic use, especially in Europe.[citation needed]

At the same time,[when?] HFC refrigerants still dominate the market. Recent government mandates have seen the phase-out of R-22 refrigerant. Replacements such as R-32 and R-410A are being promoted as environmentally friendly but still have a high GWP.[89] A heat pump typically uses 3 kg of refrigerant. With R-32 this amount still has a 20-year impact equivalent to 7 tons of CO2, which corresponds to two years of natural gas heating in an average household. Refrigerants with a high ODP have already been phased out.[citation needed]

Government incentives

[edit]

Financial incentives aim to protect consumers from high fossil gas costs and to reduce greenhouse gas emissions,[90] and are currently available in more than 30 countries around the world, covering more than 70% of global heating demand in 2021.[4]

Australia

[edit]

Food processors, brewers, petfood producers and other industrial energy users are exploring whether it is feasible to use renewable energy to produce industrial-grade heat. Process heating accounts for the largest share of onsite energy use in Australian manufacturing, with lower-temperature operations like food production particularly well-suited to transition to renewables.

To help producers understand how they could benefit from making the switch, the Australian Renewable Energy Agency (ARENA) provided funding to the Australian Alliance for Energy Productivity (A2EP) to undertake pre-feasibility studies at a range of sites around Australia, with the most promising locations advancing to full feasibility studies.[91]

In an effort to incentivize energy efficiency and reduce environmental impact, the Australian states of Victoria, New South Wales, and Queensland have implemented rebate programs targeting the upgrade of existing hot water systems. These programs specifically encourage the transition from traditional gas or electric systems to heat pump based systems.[92][93][94][95][96]

Canada

[edit]

In 2022, the Canada Greener Homes Grant[97] provides up to $5000 for upgrades (including certain heat pumps), and $600 for energy efficiency evaluations.

China

[edit]

Purchase subsidies in rural areas in the 2010s reduced burning coal for heating, which had been causing ill health.[98]

In the 2024 report by the International Energy Agency (IEA) titled "The Future of Heat Pumps in China," it is highlighted that China, as the world's largest market for heat pumps in buildings, plays a critical role in the global industry. The country accounts for over one-quarter of global sales, with a 12% increase in 2023 alone, despite a global sales dip of 3% the same year.[99]

Heat pumps are now used in approximately 8% of all heating equipment sales for buildings in China as of 2022, and they are increasingly becoming the norm in central and southern regions for both heating and cooling. Despite their higher upfront costs and relatively low awareness, heat pumps are favored for their energy efficiency, consuming three to five times less energy than electric heaters or fossil fuel-based solutions. Currently, decentralized heat pumps installed in Chinese buildings represent a quarter of the global installed capacity, with a total capacity exceeding 250 GW, which covers around 4% of the heating needs in buildings.[99]

Under the Announced Pledges Scenario (APS), which aligns with China's carbon neutrality goals, the capacity is expected to reach 1,400 GW by 2050, meeting 25% of heating needs. This scenario would require an installation of about 100 GW of heat pumps annually until 2050. Furthermore, the heat pump sector in China employs over 300,000 people, with employment numbers expected to double by 2050, underscoring the importance of vocational training for industry growth. This robust development in the heat pump market is set to play a significant role in reducing direct emissions in buildings by 30% and cutting PM2.5 emissions from residential heating by nearly 80% by 2030.[99][100]

European Union

[edit]

To speed up the deployment rate of heat pumps, the European Commission launched the Heat Pump Accelerator Platform in November 2024.[101] It will encourage industry experts, policymakers, and stakeholders to collaborate, share best practices and ideas, and jointly discuss measures that promote sustainable heating solutions.[102]

United Kingdom

[edit]

As of 2022: heat pumps have no Value Added Tax (VAT) although in Northern Ireland they are taxed at the reduced rate of 5% instead of the usual level of VAT of 20% for most other products.[103] As of 2022[update] the installation cost of a heat pump is more than a gas boiler, but with the "Boiler Upgrade Scheme"[104] government grant and assuming electricity/gas costs remain similar their lifetime costs would be similar on average.[105] However lifetime cost relative to a gas boiler varies considerably depending on several factors, such as the quality of the heat pump installation and the tariff used.[106] In 2024 England was criticised for still allowing new homes to be built with gas boilers, unlike some other counties where this is banned.[107]

United States

[edit]

Further information: Environmental policy of the Joe Biden administration and Climate change in the United States

The High-efficiency Electric Home Rebate Program was created in 2022 to award grants to State energy offices and Indian Tribes in order to establish state-wide high-efficiency electric-home rebates. Effective immediately, American households are eligible for a tax credit to cover the costs of buying and installing a heat pump, up to $2,000. Starting in 2023, low- and moderate-level income households will be eligible for a heat-pump rebate of up to $8,000.[108]

In 2022, more heat pumps were sold in the United States than natural gas furnaces.[109]

In November 2023 Biden's administration allocated 169 million dollars from the Inflation Reduction Act to speed up production of heat pumps. It used the Defense Production Act to do so, because according to the administration, energy that is better for the climate is also better for national security.[110]

Notes

[edit]

- ^ As explained in Coefficient of performance TheoreticalMaxCOP = (desiredIndoorTempC + 273) ÷ (desiredIndoorTempC - outsideTempC) = (7+273) ÷ (7 - (-3)) = 280÷10 = 28 [10]

- ^ As explained in Coefficient of performance TheoreticalMaxCOP = (desiredIndoorTempC + 273) ÷ (desiredIndoorTempC - outsideTempC) = (27+273) ÷ (27 - (-3)) = 300÷30 = 10[10]

References

[edit]

- ^

"Heat Pump Systems". Energy.gov. Retrieved 26 March 2024.

- ^ "Heat Pump Systems". US Department of Energy. Archived from the original on 27 April 2023. Retrieved 27 April 2023.

- ^ "Exhaust air heat pumps". Energy Saving Trust. Retrieved 22 February 2024.

- ^ a b c d e f g h i Technology Report: The Future of Heat Pumps. International Energy Agency (Report). November 2022. Archived from the original on 6 January 2023. Retrieved 6 January 2023. License: CC BY 4.0.

- ^ IPCC AR6 WG3 Ch11 2022, Sec. 11.3.4.1.

- ^ IPCC SR15 Ch2 2018, p. 142.

- ^ Everitt, Neil (11 September 2023). "Study proves heat pump efficiency at low temperatures". Cooling Post. Retrieved 22 January 2024.

- ^ Deetjen, Thomas A.; Walsh, Liam; Vaishnav, Parth (28 July 2021). "US residential heat pumps: the private economic potential and its emissions, health, and grid impacts". Environmental Research Letters. 16 (8): 084024. Bibcode:2021ERL....16h4024D. doi:10.1088/1748-9326/ac10dc. ISSN 1748-9326. S2CID 236486619.

- ^ a b G. F. C. Rogers and Y. R. Mayhew (1957), Engineering Thermodynamics, Work and Heat Transfer, Section 13.1, Longmans, Green & Company Limited.

- ^ a b "Is there some theoretical maximum coefficient of performance (COP) for heat pumps and chillers?". Physics Stack Exchange. Retrieved 22 February 2024.

- ^ Williamson, Chris (13 October 2022). "Heat pumps are great. Let's make them even better". All you can heat. Retrieved 22 February 2024.

- ^ "The often forgotten Scottish inventor whose innovation changed the world". The National. 10 April 2022. Retrieved 21 February 2024.

- ^ Bathe, Greville; Bathe, Dorothy (1943). Jacob Perkins, his inventions, his times, & his contemporaries. The Historical Society of Pennsylvania. p. 149.

- ^ a b c d "History of Heat Pumping Technologies in Switzerland – Texts". www.aramis.admin.ch. Archived from the original on 23 November 2021. Retrieved 14 September 2023.

- ^ Banks, David L. (6 May 2008). An Introduction to Thermogeology: Ground Source Heating and Cooling (PDF). Wiley-Blackwell. ISBN 978-1-4051-7061-1. Archived (PDF) from the original on 20 December 2016. Retrieved 5 March 2014.

- ^ Wirth, E. (1955), Aus der Entwicklungsgeschichte der Wärmepumpe, Schweizerische Bauzeitung (in German), vol. 73, pp. 647–650, archived from the original on 20 November 2021, retrieved 20 November 2021

- ^ Randall, Ian (31 July 2022). "Heat pumps: The centuries-old system now at the heart of the Government's energy strategy". Daily Express. Retrieved 16 March 2024.

- ^ a b Electricity supply in the United Kingdom : a chronology – from the beginnings of the industry to 31 December 1985. The Electricity Council. 1987. ISBN 978-0851881058. OCLC 17343802.

- ^ Banks, David (August 2012). An Introduction to Thermogeology: Ground Source Heating and Cooling. John Wiley & Sons. p. 123.

- ^ "Why Britain's homes will need different types of heat pump". The Economist. ISSN 0013-0613. Retrieved 19 February 2024.

- ^ "What is an Air-Source Heat Pump? A Complete Guide In 2024". NEWNTIDE. 24 October 2024. Retrieved 30 September 2024.

- ^ Le, Khoa; Huang, M.J.; Hewitt, Neil (2018). "Domestic High Temperature Air Source Heat Pump: Performance Analysis Using TRNSYS Simulations". International High Performance Buildings Conference. West Lafayette, IN, USA: 5th International High Performance Buildings Conference at Purdue University: 1. Retrieved 20 February 2022.

- ^ "Heat pumps show how hard decarbonisation will be". The Economist. ISSN 0013-0613. Retrieved 14 September 2023.

- ^ Lawrence, Karen. "Air source heat pumps explained". Which?. Archived from the original on 4 October 2022. Retrieved 4 October 2022.

- ^ Canada, Natural Resources (22 April 2009). "Heating and Cooling With a Heat Pump". natural-resources.canada.ca. Retrieved 22 February 2024.

- ^ "Heat pumps do work in the cold – Americans just don't know it yet". Grist. 9 May 2022. Archived from the original on 9 May 2022. Retrieved 9 May 2022.

- ^ "Heat pumps are hot items. But for people living in condos, getting one presents some challenges".

- ^ Sezen, Kutbay; Gungor, Afsin (1 January 2023). "Comparison of solar assisted heat pump systems for heating residences: A review". Solar Energy. 249: 424–445. doi:10.1016/j.solener.2022.11.051. ISSN 0038-092X.

Photovoltaic-thermal direct expansion solar assisted heat pump (PV/T-DX-SAHP) system enables to benefit the waste heat for evaporation of refrigerant in PV/T collector-evaporator, while providing better cooling for PV cells (Yao et al., 2020).

- ^ "Solar-assisted heat pumps". Archived from the original on 28 February 2020. Retrieved 21 June 2016.

- ^ "Pompe di calore elio-assistite" (in Italian). Archived from the original on 7 January 2012. Retrieved 21 June 2016.

- ^ Energy Saving Trust (13 February 2019). "Could a water source heat pump work for you?". Energy Saving Trust. Archived from the original on 4 October 2022. Retrieved 4 October 2022.

- ^ Baraniuk, Chris (29 May 2023). "The 'exploding' demand for giant heat pumps". BBC News. Archived from the original on 7 September 2023. Retrieved 19 September 2023.

- ^ Ristau, Oliver (24 July 2022). "Energy transition, the Danish way". DW. Archived from the original on 9 August 2023. Retrieved 19 September 2023.

- ^ Padavic-Callaghan, Karmela (6 December 2022). "Heat pump uses a loudspeaker and wet strips of paper to cool air". New Scientist. Archived from the original on 4 January 2023. Retrieved 4 January 2023.

- ^ Everitt, Neil (14 August 2023). "Scientists claim solid-state heat pump breakthrough". Cooling Post. Archived from the original on 24 September 2023. Retrieved 17 September 2023.

- ^ "Heat Pump Systems". U.S. Department of Energy. Archived from the original on 4 July 2017. Retrieved 5 February 2016.

- ^ "Renewable Heat Incentive – Domestic RHI – paid over 7 years". Ground Source Heat Pump Association. Archived from the original on 8 March 2018. Retrieved 12 March 2017.

- ^ "Heat Pump Efficiency | Heat Pump SEER Ratings". Carrier. Archived from the original on 14 January 2023. Retrieved 14 January 2023.

- ^ "COP and SPF for Heat Pumps Explained". Green Business Watch UK. 7 November 2019. Retrieved 22 February 2024.

- ^ "Why This Window Heat Pump is Genius – Undecided with Matt Ferrell". 11 June 2024.

- ^ "How it Works — Heat Pump Water Heaters (HPWHs)". www.energystar.gov. Retrieved 22 January 2024.

- ^ "Heat-pump hot water systems". Sustainability Victoria. Retrieved 22 January 2024.

- ^ Baraniuk, Chris (29 May 2023). "The 'exploding' demand for giant heat pumps". BBC News. Archived from the original on 7 September 2023. Retrieved 17 September 2023.

- ^ "District Heating – Energy System". IEA. Retrieved 22 January 2024.

- ^ a b David, Andrei; et al. (2017). "Heat Roadmap Europe: Large-Scale Electric Heat Pumps in District Heating Systems". Energies. 10 (4): 578. doi:10.3390/en10040578.

- ^ Sayegh, M. A.; et al. (2018). "Heat pump placement, connection and operational modes in European district heating". Energy and Buildings. 166: 122–144. Bibcode:2018EneBu.166..122S. doi:10.1016/j.enbuild.2018.02.006. Archived from the original on 14 December 2019. Retrieved 10 July 2019.

- ^ Buffa, Simone; et al. (2019), "5th generation district heating and cooling systems: A review of existing cases in Europe", Renewable and Sustainable Energy Reviews (in German), vol. 104, pp. 504–522, doi:10.1016/j.rser.2018.12.059

- ^ "Home". Annex 35. Retrieved 22 February 2024.

- ^ "Industrial Heat Pumps: it's time to go electric". World Business Council for Sustainable Development (WBCSD). Retrieved 22 February 2024.

- ^ IEA HPT TCP Annex 35 Publications Archived 2018-09-21 at the Wayback Machine

- ^ "Application of Industrial Heat Pumps. Annex 35 two-page summary". HPT – Heat Pumping Technologies. Retrieved 28 December 2023.

- ^ "Norwegian Researchers Develop World's Hottest Heat Pump". Ammonia21. 5 August 2021. Archived from the original on 23 May 2022. Retrieved 7 June 2022.

- ^ "Heat pumps are key to helping industry turn electric". World Business Council for Sustainable Development (WBCSD). Archived from the original on 24 September 2023. Retrieved 4 October 2022.

- ^ a b c d e f "Heating and cooling with a heat pump: Efficiency terminology". Natural Resources Canada. 8 September 2022. Archived from the original on 3 April 2023. Retrieved 3 April 2023.

- ^ Commission Regulation (EU) No 813/2013 of 2 August 2013 implementing Directive 2009/125/EC of the European Parliament and of the Council with regard to ecodesign requirements for space heaters and combination heaters

- ^ a b c d The Canadian Renewable Energy Network 'Commercial Earth Energy Systems', Figure 29 Archived 2011-05-11 at the Wayback Machine. . Retrieved December 8, 2009.

- ^ Technical Institute of Physics and Chemistry, Chinese Academy of Sciences 'State of the Art of Air-source Heat Pump for Cold Region', Figure 5 Archived 2016-04-14 at the Wayback Machine. . Retrieved April 19, 2008.

- ^ a b SINTEF Energy Research 'Integrated CO2 Heat Pump Systems for Space Heating and DHW in low-energy and passive houses', J. Steen, Table 3.1, Table 3.3 Archived 2009-03-18 at the Wayback Machine. . Retrieved April 19, 2008.

- ^ "How Wind Can Help Us Breathe Easier". Energy.gov. Archived from the original on 28 August 2023. Retrieved 13 September 2023.

- ^ "Global Electricity Review 2023". Ember. 11 April 2023. Archived from the original on 11 April 2023. Retrieved 13 September 2023.

- ^ a b Quaschning 2022

- ^ "The UK is sabotaging its own plan to decarbonize heating". Engadget. 27 May 2021. Archived from the original on 6 June 2021. Retrieved 6 June 2021.

- ^ Deetjen, Thomas A; Walsh, Liam; Vaishnav, Parth (28 July 2021). "US residential heat pumps: the private economic potential and its emissions, health, and grid impacts". Environmental Research Letters. 16 (8): 084024. Bibcode:2021ERL....16h4024D. doi:10.1088/1748-9326/ac10dc. S2CID 236486619.

- ^ "Can the UK rely on hydrogen to save its gas boilers?". inews.co.uk. 21 May 2021. Archived from the original on 6 June 2021. Retrieved 6 June 2021.

- ^ IEA (2022), Global Hydrogen Review 2022, IEA, Paris https://www.iea.org/reports/global-hydrogen-review-2022 Archived 2023-01-10 at the Wayback Machine , License: CC BY 4.0

- ^ Saturated vapors and saturated liquids are vapors and liquids at their saturation temperature and saturation pressure. A superheated vapor is at a temperature higher than the saturation temperature corresponding to its pressure.

- ^ Ludwig von Cube, Hans (1981). Heat Pump Technology. Butterworths. pp. 22–23. ISBN 0-408-00497-5. Archived from the original on 3 April 2023. Retrieved 2 January 2023.

- ^ Chamoun, Marwan; Rulliere, Romuald; Haberschill, Philippe; Berail, Jean Francois (1 June 2012). "Dynamic model of an industrial heat pump using water as refrigerant". International Journal of Refrigeration. 35 (4): 1080–1091. doi:10.1016/j.ijrefrig.2011.12.007. ISSN 0140-7007.

- ^ Wu, Di (2021). "Vapor compression heat pumps with pure Low-GWP refrigerants". Renewable and Sustainable Energy Reviews. 138: 110571. doi:10.1016/j.rser.2020.110571. ISSN 1364-0321. S2CID 229455137. Archived from the original on 24 September 2023. Retrieved 17 November 2022.

- ^ "Everything you need to know about the wild world of heat pumps". MIT Technology Review. Archived from the original on 1 August 2023. Retrieved 19 September 2023.

- ^ Miara, Marek (22 October 2019). "Heat Pumps with Climate-Friendly Refrigerant Developed for Indoor Installation". Fraunhofer ISE. Archived from the original on 20 February 2022. Retrieved 21 February 2022.

- ^ Rabe, Barry G. (23 September 2022). "Pivoting from global climate laggard to leader: Kigali and American HFC policy". Brookings. Archived from the original on 4 October 2022. Retrieved 4 October 2022.

- ^ Itteilag, Richard L. (9 August 2012). Green Electricity and Global Warming. AuthorHouse. p. 77. ISBN 9781477217405. Archived from the original on 23 November 2021. Retrieved 1 November 2020.

- ^ a b "Propane-powered heat pumps are greener". The Economist. 6 September 2023. ISSN 0013-0613. Archived from the original on 17 September 2023. Retrieved 17 September 2023.

- ^ "Smart CO2 Heat Pump". www.dti.dk. Archived from the original on 30 January 2023. Retrieved 17 September 2023.

- ^ "Annex 53 Advanced Cooling/Refrigeration Technologies 2 page summary". HPT – Heat Pumping Technologies. Retrieved 19 February 2024.

- ^ "Handbook for the Montreal Protocol on Substances that Deplete the Ozone Layer – 7th Edition". United Nations Environment Programme – Ozone Secretariat. 2007. Archived from the original on 30 May 2016. Retrieved 18 December 2016.

- ^ "Refrigerants – Environmental Properties". The Engineering ToolBox. Archived from the original on 14 March 2013. Retrieved 12 September 2016.

- ^ R-410A#Environmental effects.

- ^ Ecometrica.com (27 June 2012). "Calculation of green house gas potential of R-410A". Archived from the original on 13 July 2015. Retrieved 13 July 2015.

- ^ "R404 and DME Refrigerant blend as a new solution to limit global warming potential" (PDF). 14 March 2012. Archived from the original (PDF) on 14 March 2012.

- ^ a b IPCC_AR6_WG1_Ch7 2021, 7SM-26

- ^ LearnMetrics (12 May 2023). "List of Low GWP Refrigerants: 69 Refrigerants Below 500 GWP". LearnMetrics. Archived from the original on 10 June 2023. Retrieved 13 September 2023.

- ^ a b c "Global warming potential (GWP) of HFC refrigerants". iifiir.org. Archived from the original on 24 September 2023. Retrieved 13 September 2023.

- ^ Everitt, Neil (15 September 2023). "Qvantum plant has 1 million heat pump capacity". Cooling Post. Archived from the original on 24 September 2023. Retrieved 17 September 2023.

- ^ Miara, Marek (22 October 2019). "Heat Pumps with Climate-Friendly Refrigerant Developed for Indoor Installation". Fraunhofer ISE. Archived from the original on 20 February 2022. Retrieved 21 February 2022.

- ^ "Refrigerant Safety – About Refrigerant Safety, Toxicity and Flammability". Checkmark. Retrieved 17 April 2024.

- ^ "A2L – Mildly Flammable Refrigerants". ACR Journal. 1 September 2015. Retrieved 17 April 2024.

- ^ US Environmental Protection Agency, OAR (14 November 2014). "Phaseout of Ozone-Depleting Substances (ODS)". US EPA. Archived from the original on 24 September 2015. Retrieved 16 February 2020.

- ^ "Heat Pumps". IEA. Archived from the original on 17 September 2023. Retrieved 17 September 2023.

- ^ "Electrifying industrial processes with heat pumps". 22 March 2022. Archived from the original on 8 August 2022. Retrieved 9 August 2022.

- ^ Department of Energy, Environment and Climate Action, Victoria Government (Australia) (11 October 2023). "Hot water systems for businesses". Victoria Government.

- ^ Department of Energy, Environment and Climate Action (Australia), Victoria Government (23 September 2023). "Hot water systems for households". Victoria Government.

- ^ New South Wales Climate and Energy Action, New South Wales Government (Australia) (8 December 2023). "Upgrade your hot water system". NSW Government.

- ^ Australian Government, Queensland (5 October 2023). "Queensland Business Energy Saving and Transformation Rebates". Queensland Government.

- ^ Time To Save (21 November 2023). "Hot Water Rebates in Australia: A Detailed Guide For Businesses". Timetosave.

- ^ "Canada Greener Homes Grant". 17 March 2021. Archived from the original on 17 January 2022. Retrieved 17 January 2022.

- ^ "Coal fired boiler replacement in Beijing rural area". Archived from the original on 24 March 2023. Retrieved 14 September 2023.

- ^ a b c "Executive summary – The Future of Heat Pumps in China – Analysis". IEA. Retrieved 12 April 2024.

- ^ IEA (2024), The Future of Heat Pumps in China, IEA, Paris https://www.iea.org/reports/the-future-of-heat-pumps-in-china, Licence: CC BY 4.0

- ^ "The Heat Pump Accelerator Platform". European Commission. 2024. Retrieved 27 November 2024.

- ^ "Heat pumps". European Commission. 2024. Retrieved 27 November 2024.

- ^ "HMCR rates for goods and services". 11 July 2022. Archived from the original on 22 July 2022. Retrieved 24 August 2022.

- ^ "Apply for the Boiler Upgrade Scheme". Archived from the original on 19 September 2023. Retrieved 14 September 2023.

- ^ "BBC Radio 4 – Sliced Bread, Air Source Heat Pumps". BBC. Archived from the original on 30 April 2022. Retrieved 30 April 2022.

- ^ Lawrence, Karen (3 May 2024). "Air source heat pump costs and savings". Which?. Retrieved 7 June 2024.

- ^ "Clean Heat without the Hot Air: British and Dutch lessons and challenges". UKERC. Retrieved 7 June 2024.

- ^ Shao, Elena. "H. R. 5376 – Inflation Reduction Act of 2022". Congress.gov. U.S. Congress. Archived from the original on 17 November 2022. Retrieved 17 November 2022.

- ^ "As Heat Pumps Go Mainstream, a Big Question: Can They Handle Real Cold?". The New York Times. 22 February 2023. Archived from the original on 11 April 2023. Retrieved 11 April 2023.

- ^ Frazin, Rachel (17 November 2023). "Biden administration uses wartime authority to bolster energy efficient manufacturing". The Hill. Retrieved 29 November 2023.

Sources

[edit]

IPCC reports

[edit]

- IPCC (2021). Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S. L.; et al. (eds.). Climate Change 2021: The Physical Science Basis (PDF). Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press (In Press).

- Forster, P.; Storelvmo, T.; Armour, K.; Collins, W. (2021). "Chapter 7: The Earth's energy budget, climate feedbacks, and climate sensitivity Supplementary Material" (PDF). IPCC AR6 WG1 2021.

- IPCC (2018). Masson-Delmotte, V.; Zhai, P.; Pörtner, H.-O.; Roberts, D.; et al. (eds.). Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty (PDF). Intergovernmental Panel on Climate Change. https://www.ipcc.ch/sr15/.

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifta, S.; et al. (2018). "Chapter 2: Mitigation Pathways Compatible with 1.5°C in the Context of Sustainable Development" (PDF). IPCC SR15 2018. pp. 93–174.

- IPCC (2022). Shula, P. R.; Skea, J.; Slade, R.; Al Khourdajie, A.; et al. (eds.). Climate Change 2022: Mitigation of Climate Change (PDF). Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge, UK and New York, New York, USA: Cambridge University Press (In Press). Archived from the original (PDF) on 4 April 2022. Retrieved 10 May 2022.

- IPCC (2022). "Industry" (PDF). IPCC AR6 WG3 2022.

Other

[edit]

- Quaschning, Volker. "Specific Carbon Dioxide Emissions of Various Fuels". Retrieved 22 February 2022.

External links

[edit]

Media related to Heat pumps at Wikimedia Commons

Media related to Heat pumps at Wikimedia Commons

Heating, ventilation, and air conditioning

Authority control databases: National  |

|